Your Comprehensive Resource for FTTH cable Production Line

Here’s a complete overview of the FTTH cable production line. Within this comprehensive article, we will examine fiber optic cables and their indispensable role in allowing high-speed data transmission. The continuous growth in demand for faster and more reliable internet connectivity makes it essential to understand the details of FTTH cable production. This guide will furnish you with valuable insights into the production of compact fiber unit, starting with the basics of cable infrastructure and moving through the step-by-step manufacturing process.

No matter if you’re a newcomer to the industry or aiming to better your understanding, this guide will help you. We aim to explore the main parts of FTTH cable systems, the significance of optical fibers in FTTH technology, and the transformation of raw materials into high-quality fiber optic cables. Moreover, we will examine design considerations, stranding techniques, buffering and jacketing processes, and the efficient working of the FTTH cable production line.

Keep reading to learn about the advanced technologies that are changing FTTH cable manufacturing, along with the significance of testing and quality assurance in guaranteeing the reliability and durability of fiber optic cables. Also, we will examine the last phases of packaging and distribution, ensuring the FTTH cable production line functions smoothly from the initial stage to the final one.

Key Takeaways:

- FTTH cable production line plays a vital role in providing high-speed data transmission.

- It’s crucial to understand the fundamentals of FTTH cable infrastructure and its main components.

- The step-by-step production of FTTH cable, starting with silica and resulting in fiber, includes fiber drawing, coating application, and testing.

- Designing configurations and layouts that meet specific network requirements can optimize performance.

- Fiber benefits from the added support and protection offered by stranding techniques and central strength members.

Fundamentals of FTTH cable Production

A clear understanding of the cable infrastructure, key components, and the role of optical fibers in FTTH technology is essential to comprehend the FTTH cable production process.

Getting to Know the FTTH cable Infrastructure

The FTTH cable infrastructure is the system of cables, connectors, and distribution points that makes data transmission possible in fiber-to-the-home (FTTH) systems. This infrastructure serves as the foundation for high-speed internet connectivity, enabling smooth data transfer between the network of the provider and the location of the end user.

Important Components of FTTH cable Systems

FTTH cable systems consist of several key components that work together to ensure the smooth and efficient transmission of data. These components include:

- The data signals are carried by these fiber optic cables in the form of light. They are designed to provide high bandwidth and low signal loss, ensuring fast and reliable data transmission.

- Playing a crucial role, connectors join fiber optic cables to other cables or devices, making it easy to connect and disconnect them when necessary. A secure and reliable connection is provided by them, which helps minimize signal loss.

- Multiple end users receive divided and distributed fiber optic signals through the use of distribution points. Their purpose is to help each user receive the correct amount of bandwidth while maintaining the overall network performance.

How Optical Fibers Contribute to FTTH Technology

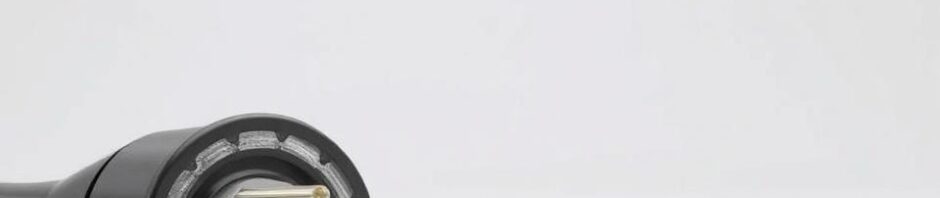

FTTH technology relies heavily on optical fibers. Made of thin strands of glass or plastic, they are designed to efficiently transmit data signals in the form of light pulses. Optical fibers are known for their high bandwidth capacity, low signal loss, and immunity to electromagnetic interference, making them ideal for high-speed data transmission.

These fibers consist of a core that transmits light signals, and this core is surrounded by a cladding layer that reflects the light back in, preventing signal loss. This design enables optical fibers to carry data over long distances without the signal quality or speed getting worse.

Step-by-Step Process: From Silica to Fiber

How Fiber Drawing Creates the Core of the cable

Fiber drawing is the initial step in the FTTH cable production process, and it’s where the cable’s core is made. A glass preform made of silica is pulled and stretched in this process, turning it into a long, thin fiber. The diameter of the fiber is precisely controlled during fiber drawing to guarantee optimal performance. A crucial factor in the cable’s efficient and accurate data transmission is the quality and composition of its core.

The Importance of Coating Application in cable Durability

Coating application is the step that follows fiber drawing. At this point, a protective layer, referred to as a coating, is applied to the fiber. As a buffer against external factors such as moisture, the coating serves several purposes, including enhancing the fiber’s long-term durability and reliability. Additionally, the coating material used is carefully selected to have the appropriate mechanical properties, ensuring that the fiber remains intact and protected throughout its lifespan.

Quality Assurance: Fiber Testing at All Stages

To ensure the fiber’s quality and performance, fiber testing is performed at different stages throughout the FTTH cable production process. Testings include measuring the fiber’s physical parameters such as diameter, attenuation, and tensile strength, as well as inspecting the coating’s uniformity and adhesion properties. It’s crucial to perform these tests to make sure the fiber meets the necessary standards and specifications, which guarantees the overall quality and performance of the final FTTH cables.

| Production Stage | Parameters Tested |

|---|---|

| Fiber Drawing | Diameter, Attenuation, Tensile Strength |

| Coating Application | Coating Thickness, Uniformity, Adhesion |

A Table Summarizing Testing Parameters at Different Stages of FTTH cable Production

The testing parameters measured at different stages of the FTTH cable production process are summarized in the table above. Manufacturers can ensure that every fiber used in the cables meets the necessary quality standards by performing thorough testing, which ultimately leads to the high-performance and reliability of FTTH cable systems.

Design Considerations for FTTH cable Configurations

The design of cable configurations is a vital aspect of fiber-to-the-home (FTTH) cable production, as it helps meet network requirements and optimize performance. When designing a cable, you need to consider the network’s capacity, how scalable it is, and the desired speed for data transmission. Companies can make sure their network infrastructure is deployed efficiently and its capabilities are maximized by customizing cable configurations to meet specific needs.

A variety of FTTH cable configurations and layouts are available, and each has its own advantages and considerations:

- The main distribution point is connected to each subscriber in a sequential manner in the Daisy Chain Configuration. This cost-effective solution is ideal for regions with a low number of subscribers.

- Star Configuration: In the star configuration, each subscriber is directly connected to the central office or hub. This design provides flexibility and ease of maintenance, making it ideal for densely populated areas.

- A circular loop connection of subscribers is what defines the ring configuration. It offers redundancy and fault tolerance, ensuring uninterrupted service in case of network failures.

- Tree Configuration: In a tree configuration, the main distribution point is connected to secondary distribution points, which then connect to individual subscribers. Efficient network expansion is possible with this configuration, making it suitable for areas with a high density of subscribers.

- Distribution points have multiple connections between them in the mesh configuration, which provides high reliability and redundancy. For applications where it’s essential that service never be interrupted, this configuration is commonly used.

When designing FTTH cable configurations, it is essential to consider the network requirements and expected future growth. The best configuration to choose depends on things like how many subscribers there are, where they are located, and what kind of service they need, as each configuration has its own advantages and disadvantages.

By carefully evaluating these factors and collaborating with industry experts, companies can develop customized FTTH cable configurations that meet their specific network requirements and deliver optimal performance.

Stranding: Techniques and Machinery

Stranding techniques and equipment are essential in the production of FTTH cables to guarantee their strength and durability. Various stranding patterns are used, and each one has its own benefits and is suitable for different purposes. The efficiency and quality of cable production depend on choosing the appropriate stranding machinery. In addition to stranding techniques, central strength members offer extra support and protection to the fiber, which helps make the FTTH cables more reliable overall.

A Look at Different Stranding Patterns

When producing FTTH cables, one of the main things to consider is which stranding pattern to use. Depending on what characteristics are desired in the cable, different stranding patterns are used, such as reverse concentric, SZ stranding, and helical stranding. The cable’s performance in terms of flexibility, strength, and resistance to external factors can be enhanced by the unique features offered by each pattern. To make sure the FTTH cables perform as well as possible and last a long time, stranding patterns are carefully chosen to meet the specific needs of the application.

Factors to Consider When Choosing Stranding Machinery

Without stranding machinery, the FTTH cable production line wouldn’t function. The stranding pattern can be precisely formed thanks to this machinery, which also keeps the fibers at the necessary tension and in the correct alignment. When selecting the right fiber secondary coating line machinery, you need to consider things like the cable’s diameter, the speed of production, and the level of automation you need. With advanced stranding machines, manufacturers can be more efficient and flexible, which allows them to produce large quantities of cables and also customize them.

Understanding Central Strength Members

Central strength members are used in FTTH cables to enhance their mechanical properties. They provide stability, improve tensile strength, and protect the delicate fiber within the cable. The cable structure is reinforced by central strength members, which act like a backbone and are typically made of materials like aramid or fiberglass, helping it resist external forces. Because they are there, FTTH cables can handle the stresses of being installed and keep the signal transmission working properly, which makes them good for different ways of deploying them.

Protecting the Fiber: An Explanation of Buffering and Jacketing

During the production of FTTH cables, the buffering and jacketing processes are crucial for safeguarding the delicate fiber inside. These processes make sure the fiber is protected from a range of possible threats, including moisture, wear and tear, and other external elements that could put its performance and lifespan at risk.

The Buffering Process and Its Importance

The buffering process involves applying a protective layer around the fiber, acting as a barrier against environmental elements. Water from getting in is prevented by this layer, which can lead to the signal getting weaker or even the fiber breaking. Buffering also improves how well the cable resists abrasion, which means there’s less chance of damage when it’s being put in or looked after.

The buffering materials that are used must stick to the fiber excellently and have a low coefficient of friction to keep stress on the fiber to a minimum. Choosing the right buffering material depends on things like what kind of environment the cable will be in and how much protection is needed.

How to Select Jacketing Materials

Putting an outer layer on to give extra protection to the fiber and the buffering materials is what jacketing involves. The jacketing material is specifically chosen to provide robust protection against mechanical stress, impact, UV radiation, and other potential hazards.

When selecting jacketing materials, you need to think about things like flexibility, how well it resists fire, and if it’s compatible with the environment. You’ll often find jacketing made from materials like polyethylene (PE), polyvinyl chloride (PVC), and low-smoke zero-halogen (LSZH) compounds. The specific application and what the industry standards are will determine which material is chosen, as each one has its own pros and cons.

How Latest Jacketing Technologies are Applied

Jacketing technologies have come a long way, and these advancements have completely changed how FTTH cables are protected. With the newest technologies, you get better strength, more flexibility, and better resistance to things in the environment, which means they last longer and are more reliable.

With tight-buffered cables, an innovative jacketing technology, each fiber is individually buffered with a thin layer of plastic, providing excellent protection and flexibility. Another technology is micro-ducts, which use rugged tubing to house multiple fibers, offering high-density and versatility in cable installation.

Furthermore, there are specialized jacketing technologies designed to meet specific industry requirements. For instance, cables used in harsh outdoor environments might incorporate armored jackets, providing superior protection against rodents, moisture, and extreme temperatures.

FTTH cables can be tailored to meet the needs of different applications by using the latest jacketing technologies, which guarantees the best performance, a long lifespan, and reliability.

The Workings of the FTTH cable Production Line

To have a smooth and streamlined manufacturing process in the FTTH cable production line, efficient operations are crucial. Producing high-quality fiber optic cables that allow for high-speed internet connectivity depends on each step in the production line playing a vital role. To achieve optimal efficiency, various machinery and equipment are utilized.

Preparation of raw materials, including the silica for fiber drawing, is the initial stage of the manufacturing process. The process then moves on to fiber drawing, where the cable’s core is carefully made to achieve the desired specifications. The next step is coating application, which provides durability and protection for the fiber.

To make sure the cables meet the highest standards, quality is the most important thing, and thorough fiber testing is done at every step of the production line. This includes testing for factors like attenuation, bandwidth, and signal loss.

For the FTTH cable production line to work well, efficiency is very important. Using machinery and equipment in the most efficient way allows manufacturers to reduce production time and costs and also produce the maximum amount. The overall quality of the cables is also improved by having efficient processes.

The manufacturing process can be complicated, with various stages and components involved. However, by integrating efficient operations and continuous improvement initiatives, manufacturers can improve the efficiency and effectiveness of their FTTH cable production line.

The table below provides a summary of the key machinery involved in the FTTH cable production line and their respective roles in the manufacturing process, giving you a comprehensive understanding of the operations:

| Machine | Role |

|---|---|

| Fiber Drawing Machine | Produces the fiber optic cable core by pulling and stretching the silica material. |

| Coating Machine | Applies a protective coating to the fiber optic cable, ensuring durability and resistance to external factors. |

| Fiber Testing Equipment | Conducts various tests on the fiber optic cable to ensure quality and performance. |

| Spooling Machine | Winds the finished fiber optic cable onto spools for packaging and distribution. |

| Jacketing Machine | Applies an outer jacket to the fiber optic cable, providing additional protection and enhancing its handling. |

Manufacturers can make their production line operations more efficient, enhance how well they work, and provide high-quality FTTH cables that meet the growing need for high-speed internet connectivity by using advanced machinery and technologies.

How Advanced Technologies are Transforming FTTH cable Manufacturing

In the constantly evolving field of FTTH (Fiber to the Home) cable manufacturing, advanced technologies play a crucial role in improving efficiency and quality. Automation, AI integration, and fiber coloring machines have completely changed the production process due to the increasing demand for high-speed data transmission, which has driven innovation and led to the creation of superior products.

How Automation is Used in Fiber Optic cable Production

Manufacturing of fiber optic cables has been greatly changed by automation. With advanced machinery and robotics, the manufacturing process can be controlled with great precision, ensuring consistent quality and minimizing errors. This automation results in higher productivity, faster production, and better accuracy, which ultimately saves money and enhances how satisfied customers are.

How AI is Integrated for Quality Control

FTTH cable manufacturers can reach unprecedented levels of accuracy and reliability by integrating artificial intelligence (AI) into their quality control process. AI algorithms can analyze production data in real-time, identifying any deviations or anomalies that may affect the quality of the cables. This way of checking quality helps to reduce mistakes, make production more efficient, and ensure that only the best FTTH cables are sold.

How Fiber Coloring Machines Work

Fiber coloring machines have completely changed how FTTH cables are made by providing more options for customization. Color codes can be applied to optical fiber strands by fiber coloring machines, which allows for easy identification and makes cable management more efficient during installation and maintenance. The need for manual color coding is eliminated by this technology, which also reduces the risk of errors and makes cable deployment more efficient overall.

Quality Assurance in Fiber Optics: The Importance of Testing

Making sure the quality is the best it can be is very important in the field of fiber optics. This is achieved by using thorough testing and quality assurance methods throughout the entire production process. Standardized testing protocols are crucial for making sure fiber optic cables are reliable and consistent.

Steps to Implement Standardized Testing Protocols

Every fiber optic cable is guaranteed to meet the required quality standards through the establishment of standardized testing protocols. These protocols detail the specific testing procedures and criteria that must be followed at each stage of the production process. Following these protocols allows manufacturers to find and fix any potential problems, making sure that only the highest quality cables are given to customers.

OTDR: A Key Tool for Quality Checks

Quality checks on fiber optic cables are incomplete without the use of Optical Time-Domain Reflectometer (OTDR). Using light pulses, OTDR is a testing tool that measures how much signal is lost and reflected along an optical fiber. Technicians can find problems like fiber bending, signal loss, or damage to connectors by looking at the OTDR traces. Finding the exact location of any problems and taking steps to fix them is made possible, which ensures the cable’s overall quality and performance.

Maintaining Rigorous Quality Assurance Standards

The consistent and reliable performance of fiber optic cables is ensured by maintaining quality assurance standards throughout the entire production process. These standards include guidelines for things like choosing materials, the manufacturing processes, and how the final product is tested. By adhering to these rigorous standards, manufacturers can ensure that their products meet the highest levels of quality and performance required by the industry.

How FTTH cables are Packaged and Distributed

Packaging and distribution, the final steps in SZ stranding line production, are what this section is about. Ensuring that the cables are packaged correctly and efficiently after they have gone through the various manufacturing processes is crucial for their deployment and installation in the field. Protective packaging solutions are also key to making sure the delicate fiber optic cables are safe during transportation and storage. It’s essential to have efficient logistics and supply chain management to ensure that FTTH products are delivered to customers in a timely way and effectively meet their connectivity needs.

Best Practices for cable Spooling

Using efficient techniques to spool cables is vital for making the installation of FTTH cables smooth and convenient. cable spools provide a practical and organized way to store and transport the cables, reducing the risk of tangling or damage. cable installers can save time and effort when deploying cables by using the best cable spooling techniques. A neat and professional appearance of the installation is ensured by properly spooled cables, which also improve the overall aesthetics.

Packaging Solutions for Safeguarding Fiber Optic cables

The delicate fiber optic cables need to be protected during transportation and storage, and this requires the implementation of effective protective packaging solutions. These solutions should provide cushioning, shock absorption, and resistance to external factors such as moisture, dust, and physical impact. The use of high-quality packaging materials and techniques ensures that the fiber optic cables will arrive at their destination in optimal condition, ready to be installed by manufacturers. By reducing the chance of damage or the cables not working as well as they should, this not only keeps the cables in good condition but also makes customers happier.

The Importance of Logistics and Supply Chain Management in FTTH

For FTTH products to be delivered to customers successfully, efficient logistics and supply chain management are crucial. To ensure timely and reliable delivery, this requires careful planning of the transportation, storage, and distribution of the cables. With effective supply chain management, delays are minimized, the flow of products is optimized, costs are reduced, and customer service is improved.

Conclusion

In summary, this ultimate guide to the FTTH cable production line has offered a comprehensive overview of the process of manufacturing fiber optic cables for high-speed internet connectivity. Throughout this article, we have emphasized how important the FTTH cable production line is for making fast and reliable data transmission possible.

High-speed internet connectivity is made possible by fiber optic cables, which play a critical role in allowing for seamless communication, streaming, and online activities. From fiber drawing to buffering and jacketing, the step-by-step process of FTTH cable production makes sure these cables are durable and of high quality.

Technologies like automation and AI integration, which are advanced, have completely changed the manufacturing process, leading to increased efficiency and accuracy. Also, the reliability and performance of fiber optics are guaranteed by following standardized testing protocols and strict quality assurance standards.

Packaging and distribution are the final steps in FTTH cable production, ensuring that these essential cables are efficiently deployed and protected during transportation. Meeting the increasing global demand for high-speed internet connectivity relies on the expertise and precision involved in the FTTH cable production line.