Shurflo Water Pump Schematic – Installation Components Supply

Incorrect installation of water pumps can substantially diminish their effectiveness by up to 30%. It’s vital to comprehend the mechanics of the Shurflo Pump schematic for maximum efficiency and robustness. Each component within the diagram plays a crucial role in the operation of the Pump. We’ll dive into the importance of understanding these Shurflo pumps parts, utilizing the diagram to show their assembly and how they work together.

Installation Parts Supply is your go-to for every Shurflo Water Pump component required for setup and maintenance. Learning via the Shurflo Pump parts diagram enables users to expertly handle installation and maintenance. This knowledge assists in creating informed choices for the optimal and reliable performance of their Water Pump units.

Grasping Shurflo Water Pumps

Shurflo Pump systems are at the intersection of modernity and utility, fulfilling the requirements of multiple functions. This section seeks to provide an in-depth overview of Shurflo Water Pump models, their specific uses, and the merits of opting for these devices. They are celebrated for their technological sophistication and efficiency.

Summary of Shurflo Pump Models

Shurflo’s range includes pumps like the diaphragm and agricultural series, designed for diverse requirements. The diaphragm models are praised for their robust build and efficiency in moving liquids. Examples such as the 2088-343-135 and 2088-343-500 offer powerful output with remarkable flow and pressure capabilities.

The farm series, conversely, is designed for effective fluid transport in agricultural settings.

Implementations of Shurflo Pump Systems

The adaptability of Shurflo Pump systems permits their use in a variety of settings. They are frequently employed in:

- Farming: Delivers options for watering and nutrient application.

- Motorhomes: Maintains a steady water flow with regulated pressure settings.

- Domestic: Perfect for landscaping and home fluid systems.

This versatility allows these Pump systems to blend seamlessly with diverse configurations, demonstrating their multifunctionality.

Merits of Using Shurflo Pump Systems

Selecting Shurflo Pumps brings several perks. Their ability to self-prime erases the inconvenience of manual operation startup. They also have chemical resistance, ensuring longevity in harsh environments. Easy access to Shurflo membrane Water Pump parts simplifies upkeep, extending operational longevity while minimizing interruptions. Additional benefits of Shurflo Pumps comprise:

- Stable performance that can be customized with adjustable pressures.

- Simple setup aided by an extensive parts catalog.

- Various connection options for smooth system integration.

With these attributes, Shurflo Pumps promise efficiency and reliability. They ensure operation continuity, instilling trust in their performance.

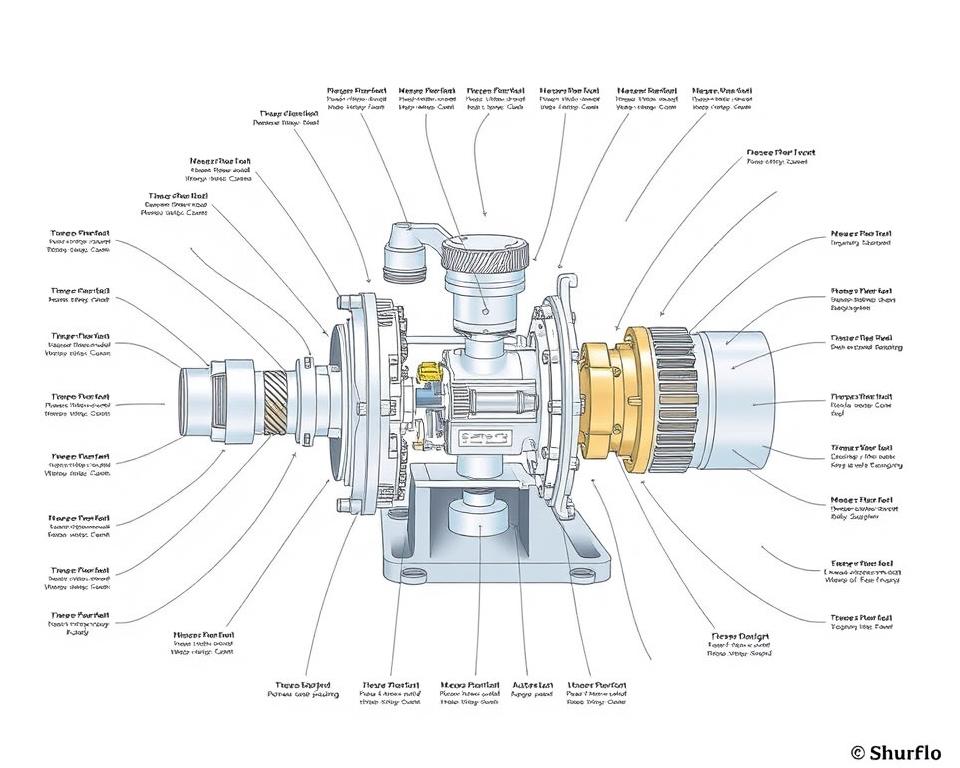

Shurflo Water Pump Diagram and Its Importance

The Shurflo Water Pump diagram is critical for grasping its elements and operations. By studying the Shurflo Water Pump schematic, users can put together, diagnose, and maintain efficiency. This schematic is vital for identifying the necessary Shurflo Pump parts. Accurate assembly facilitated by the schematic ensures peak performance.

Primary Parts in the Schematic

The Shurflo Water Pump assembly diagram showcases critical components necessary for proper operation:

- Motor: The engine, the heart of the Pump, drives the rotor, enabling flows from 41 to 168 GPM.

- Diaphragm: Helps sustain consistent flow and pressure.

- One-Way Valves: Essential for blocking reverse flow, these devices ensure that fluid flows in the right direction.

- Housing: With a max pressure of 200 PSI, the housing maintains structural integrity.

How to Read the Shurflo Water Pump Schematic

To analyze the Shurflo Pump schematic, one must note particular icons and labels:

- Learn the arrangement of components depicted in the diagram.

- Recognize the indicated flow path via directional arrows.

- Check notes for details like wire sizes and mounting options.

Mastering this diagram is essential for proper assembly, maintenance, and identifying key components.

Fitting Shurflo Water Pumps

Setting up a Shurflo Water Pump can make any water system more functional. Knowing the necessary steps and components is vital for a good installation. This guide covers key actions and required instruments for a successful setup.

Sequential Directions for Setting Up a Shurflo Pump

- Begin by gathering all tools for shurflo pump installation. Ensure possession of tools such as the correct screwdriver, wrench, plus a 50-mesh strainer.

- Put the 50-mesh strainer on the pump’s inlet side. It’s best to use a pliant hose for connecting the inlet to minimize strain on fittings.

- Apply a 1/2” to 3/8” barb splicer for connecting tubing securely. To prevent leakage, choose durable tubing equipped with Oetiker clamps.

- The pump should be wired to a properly grounded outlet. A licensed electrician must perform this to adhere to local codes.

- Charge the accumulator tank with 50 PSI of clean air or nitrogen. This is crucial for optimal pressure output.

- Mount a SHURflo 65 psi pressure reducer at the Pump’s inlet to secure the proper pressure setting.

- Finalize the configuration by joining every element. Avoid overloading the motor’s amperage; incorporate thermal breakers for additional safety.

- Conduct a system test and verify the pressure switch operates correctly.

Installation Essentials: Tools and Parts

| Item | Details |

|---|---|

| 50-mesh strainer | Filters debris at the pump’s inlet to ensure optimal performance. |

| Pliable hose | Recommended for inlet connections, reduces strain on fittings. |

| Barb splicer | 1/2” to 3/8” connection for secure tubing attachment. |

| Pressure tank | Pre-charged to 50 PSI for maintaining pressure. |

| Switch | Regulates operation by monitoring pressure conditions. |

| Electrical supplies | Essential for proper electrical hookup, following local codes. |

| SHURflo 65 psi valve | Ensures steady pressure by reducing the water pressure at the inlet. |

Diagnosing Frequent Problems in Shurflo Pumps

Learning to fix common issues with shurflo pumps improves their functionality. This segment provides a troubleshooting guide. It assists in identifying and remedying common issues to ensure smooth operation of the pumps. Problems related to operation, flow, and acoustics are addressed with effective fixes.

Typical Issues and Remedies

Various conditions may result in malfunctions with Shurflo Pumps. Here is a list of frequent problems with corresponding remedies:

- Pump runs but no water flow: Check the freshwater tank level, inspect the water line for blockages or damage, ensure proper priming, and verify the water pump’s functionality.

- Pump won’t turn on after winterization: Examine winterization methods, ascertain all valves are operable, inspect electrical setups, and search for signs of damage.

- Pump intermittently starting and stopping: Look for any leaks, remove trapped air, adjust pressure controls accordingly, and test both the Pump and its pressure switch.

- Noisy pump: Check for unsecured fittings, incorporate vibration dampening, insulate piping, and verify correct mounting.

Troubleshooting Manual for Shurflo Pumps

A detailed Shurflo Water Pump troubleshooting guide aids in swift diagnosis. Below is a summary table of common problems with solutions:

| Common Issue | Potential Causes | Solutions |

|---|---|---|

| Operation without liquid movement | Insufficient water level, obstructions, inadequate priming | Assess water level, inspect for clogs, test Pump performance |

| Pump won’t turn on | Faulty winterization, sealed valves, power connection problems | Reexamine procedures, unlock valves, inspect electrical links |

| Intermittent cycling | Leaks, air in system, pressure issues | Check system integrity, purge air, calibrate pressure |

| Noisy pump | Unsecured fittings, poor mounting | Tighten connections, add padding, insulate pipes |

Understanding the shurflo pump exploded view helps users pinpoint components behind common issues is essential for accurate diagnosis. Following these recommendations secures consistent performance and upkeep.

The Bottom Line

Comprehending the Shurflo Water Pump diagram is key for optimal Pump operation.

Used in diverse environments including RVs and farming, a precise setup is imperative for consistent performance.

Familiarity with the diagram’s elements allows for efficient installation and sustained maintenance.

Installation Parts Supply is paramount for obtaining all needed Shurflo pump parts and services, providing complete assistance with access to crucial equipment and parts. This ensures effective setups. By using appropriate plumbing and wiring and maintaining components like the strainer, the longevity and efficiency of the pumps are enhanced.

This article arms users with the necessary knowledge to optimize Shurflo system performance. Employing Shurflo Pump technology alongside these installation recommendations readies users to overcome any obstacles confidently.