Tailored Cosmetic Bag Producer: Custom Beauty Cases

The global cosmetic bag market is set to hit $5 billion by 2025. This surge in demand shows a clear preference for stylish, functional bags for beauty products. Being a premier cosmetic bag maker, we strive to deliver unique designs that delight and serve functional purposes. Partnering with brands, we produce superior, bespoke cosmetic bag manufacturer capturing brand spirit

Essential Insights

- Market forecasts show $5 billion in cosmetic bag sales by 2025

- Custom bags for beauty are tailored to meet specific brand and consumer needs

- Custom beauty bag makers emphasize craftsmanship and aesthetics

- Collaboration with manufacturers helps brands establish their unique identity

- Practicality and style drive cosmetic bag success

Understanding the Role of a Cosmetic Bag Manufacturer

A cosmetic bag maker plays a vital role in beauty markets. They link brands and end-users. These manufacturers specialize in creating custom cosmetic bags that meet the specific needs of beauty brands. They ensure each bag aligns with the brand’s aesthetics and fulfills functional requirements.

In a cutthroat industry, an appealing cosmetic bag is crucial. It holds beauty essentials and doubles as a promotional asset. A high-quality cosmetic bag boosts the product’s appeal and strengthens the brand’s identity.

Knowing industry hurdles helps manufacturers innovate effectively. Options span materials, styles, and dimensions. Selecting the right manufacturer is critical for a brand’s success in a fast-paced market.

Custom Bag Varieties

Cosmetic bag manufacturers offer a wide variety of custom bags to suit different needs. Custom PVC cosmetic bags stand out for their durability and water resistance. Ideal for holding makeup and liquids. Plus, they are easy to clean, adding to their practicality.

Custom velvet cosmetic bags, on the other hand, bring a touch of elegance and luxury. Velvet’s plush feel lends refined style. It attracts customers who appreciate premium touches and wish to improve brand perception.

Understanding bag options aids brands in selecting wisely. A well-chosen bag elevates brand presence and satisfies user tastes.

Why Pick Custom Cosmetic Bags

Tailored beauty bags provide major brand benefits. They enhance brand recognition through logo placement. Thus, they act as effective promotional items remembered by users.

Custom bag producers craft styles for diverse consumer preferences. This customization helps brands stand out in a crowded market. It encourages customers to choose products that reflect their personal style and needs.

Custom bags foster stronger customer loyalty. A well-made, attractive bag builds brand connection. Such rapport drives repeat business and referrals.

Working with a branded cosmetic case producer simplifies the creative process and ensures a professional finish. This collaboration helps brands share their story, strengthening their marketing efforts and making a lasting impact on their audience.

Material Options for Custom Cosmetic Bags

Choosing the right materials for custom cosmetic bags is key to their appeal and functionality. Options include numerous fabrics to suit different tastes and trends. The PVC cosmetic bag is notable for its durability and water resistance, ideal for daily use.

Velvet bags add a luxurious vibe, drawing high-end customers. Velvet’s luxurious feel and sophisticated look are highly sought after by brands. It’s critical for brands to grasp these material traits to match their packaging with their branding goals.

Whether it’s the practicality of PVC or the stylish look of velvet, understanding each material’s benefits helps brands make better choices. Opting for the right materials can boost customer happiness and loyalty to the brand.

Production Capacity of a Leading Cosmetic Bag Manufacturer

A leading cosmetic bag manufacturer has an impressive production capacity. They often produce over 90,000 units monthly. Such volume lets brands scale orders with demand and seasons. Quality remains uncompromised.

These manufacturers operate in facilities of at least 25,000 square meters. They have a team of over 200 skilled employees. This structure guarantees fast production and premium bags adhering to rigorous criteria.

High-volume capability makes them a dependable ally. They support brands in expanding offerings without sacrificing customer happiness.

Custom OEM and ODM Solutions

In the cosmetic industry, OEM and ODM services are key for brands wanting unique cosmetic bags. They enable deep co-creation with makers to fulfill exact designs. OEM aids brands in crafting signature products with consistent quality. It fosters creativity and innovation, crucial for standing out.

ODM provides end-to-end design services aligned with trends and market needs. Brands leverage seasoned designers familiar with market shifts. They bring concepts to life, enhancing product lines and speeding development. This leads to faster market entry and better efficiency.

Choosing OEM and ODM services is a strategic move for brands aiming to strengthen their beauty market presence. Using such bespoke services, brands create unique bags resonating with consumers.

| Service Type | Description | Benefits |

|---|---|---|

| OEM Services | Adapting current designs for brand needs | Exclusive branding opportunities, enhanced product quality |

| ODM Services | End-to-end design and production | Expert design, quicker launch |

| Tailored Solutions | Personalized approaches based on brand vision | Distinctive products, solid positioning |

Bag Production Quality Control

QA is crucial in PVC cosmetic bag. It ensures every cosmetic bag meets and often surpasses industry standards. They perform rigorous tests on strength, material rules, and visual excellence.

Brands should pick pouch suppliers with robust QA measures. Early defect detection ensures a final product upholding brand standards. Adherence to bag manufacturing standards is key, proving the manufacturer’s reliability.

High-quality assurance practices build trust between suppliers, manufacturers, and clients. This dedication to excellence means customers get stylish, practical, and durable products.

Fast Fashion Impact on Bag Making

The cosmetic bag manufacturing industry has seen a significant shift with the emergence of fast fashion trends. Brands now seek manufacturers who can quickly move from idea to production. Such speed requirements shape bag design and manufacturing.

Adaptability is vital for producers to match consumer shifts. Trends can shift rapidly, making it critical for manufacturers to stay ahead. Maintaining a diverse range of styles and designs is vital. It enables brands to meet the needs of a broad audience looking for the newest beauty accessories.

Manufacturers who excel in cosmetic bag production must be flexible. This flexibility is not just about meeting demand but also about staying competitive in a crowded market. Agility is key to thriving in fast-fashion contexts.

Collaborations with Top Brands

Collaborating with well-known brands can greatly improve a cosmetic bag manufacturer’s standing in the market. Such alliances highlight maker expertise and brand credibility. That collaboration yields distinctive products aligned with market demand.

Partnering with renowned brands boosts exposure and market knowledge. Such interaction fosters innovation, compelling makers to evolve. Leveraging these brand ties, firms can lead the cosmetic bag sector.

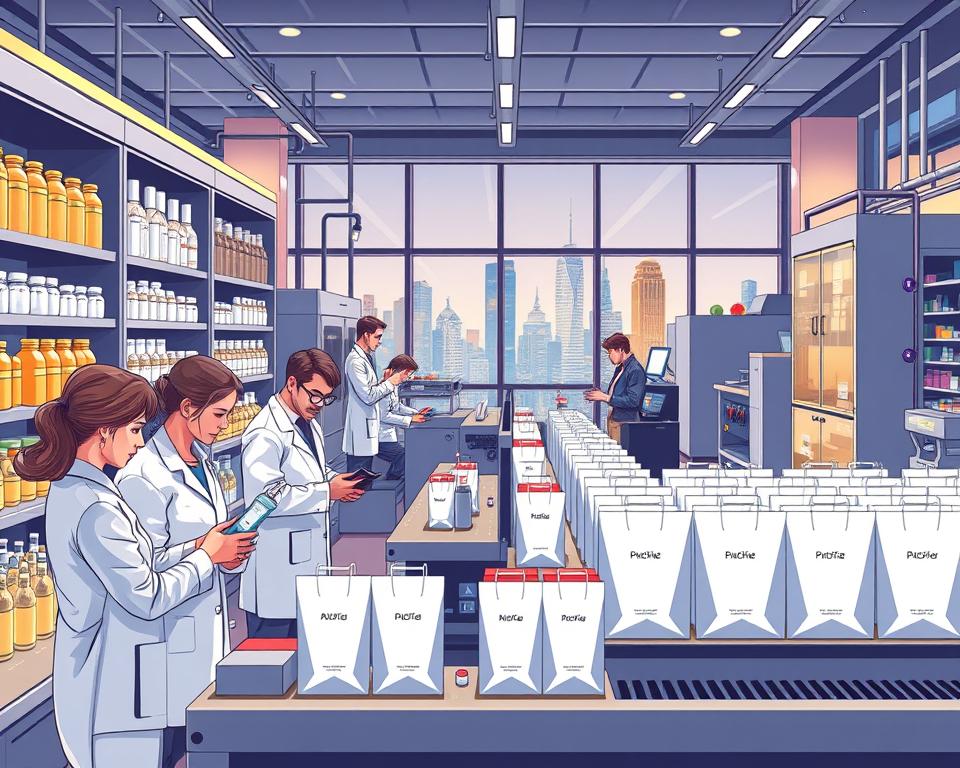

Visiting a Makeup Bag Factory

Touring a custom bag factory reveals in-depth production steps. Every step—from design draft to assembly—is vital for top-tier products. Brands must grasp factory operations when seeking manufacturing partners.

Inside, you witness each stage forming the final bag. Design and engineering teams collaborate on creative, functional concepts. After prototypes pass inspection, the production process starts, involving cutting, sewing, and quality checks.

Production efficiency is vital to satisfy market needs. They employ modern tech and expert staff to streamline processes. The focus on quality control ensures every product meets standards before it reaches consumers.

Knowing production workflows guides brands in selecting partners. Exploring a factory’s materials and skills reveals what sets leading makers apart.

Selecting the Best Pouch Supplier

Choosing the right cosmetic pouch supplier is critical for any beauty brand. A thorough evaluation should consider several key factors for a successful partnership. Start by evaluating their output capability. Ensure they handle your volumes and deadlines.

Material choices are another key factor. Verify they employ premium materials meeting your specs. Superior materials enhance appeal and drive loyalty.

Reviewing past custom velvet cosmetic bag prototypes shows skill and dependability. Reviews and feedback from other clients also shed light on their reputation. Communication quality impacts collaboration; assess their responsiveness on design and schedule.

Ultimately, a comprehensive review of capacity, quality, and communication ensures the right supplier match.

Branded Cosmetic Case Producers: What to Look For

Choosing the right branded cosmetic case producer involves several key considerations. Look for manufacturers with a strong track record and glowing reviews from past clients. This reveals their true competencies. Durability and excellence are non-negotiable.

Assessing design adaptability is crucial. Unique designs can make your products stand out in a crowded market. Hence, early branding choices matter greatly. A reliable partnership with a quality manufacturer can lead to outstanding products, boosting your brand’s visibility and customer loyalty.

To Summarize

Choosing the right cosmetic bag manufacturer is key for beauty brands aiming to boost their marketing and look. The wide range of materials and production capacities means brands have many factors to weigh. These decisions greatly affect their overall brand image.

Custom bags are more than just containers for makeup; they reflect a brand’s identity and values. Choosing a partner aligned with their goals lets brands craft items resonating with customers. That synergy drives loyalty and boosts revenue.

Selecting a bag maker is a tactical decision, not merely operational. With careful thought and a focus on quality and innovation, beauty brands can enhance their branding. They can also deliver products that make a lasting impact.

Frequently Asked Questions

Which cosmetic bag styles are available?

Producers supply many bag types: PVC, velvet, and organizer styles. Each type caters to different needs, from practicality to luxury appeal.

What are the perks of custom cosmetic bags?

Bespoke bags raise brand awareness and set you apart. They meet specific consumer preferences, serving as both packaging and marketing tools.

Is bespoke design possible with the maker?

Yes! Many manufacturers provide OEM and ODM services. This allows brands to work closely and create exclusive designs that match their vision.

Which materials can be used for bags?

Options span PVC, velvet, and assorted textiles. Each material suits different market segments and customer preferences.

How to pick a cosmetic pouch partner?

Assess based on output scale, design flexibility, and QA. A strong portfolio and positive testimonials are key to ensuring a reliable partnership.

What is the average production capacity of a leading cosmetic bag manufacturer?

A leading manufacturer can produce over 90,000 units monthly. This capacity supports flexible ordering with market and seasonal shifts.

Why focus on QA in bag production?

QA guarantees bags adhere to durability and style norms. Reliable suppliers conduct thorough testing to prevent defects. Thus, you receive bags that uphold brand excellence.

How do trends influence bag manufacturing?

Fast fashion demands flexibility from producers. They need to pivot fast for design shifts and consumer trends.

Key factors for choosing case manufacturers

When choosing a branded cosmetic case producer, look at their project portfolio, design flexibility, and quality commitment. Their ability to communicate and collaborate with your brand is also essential.